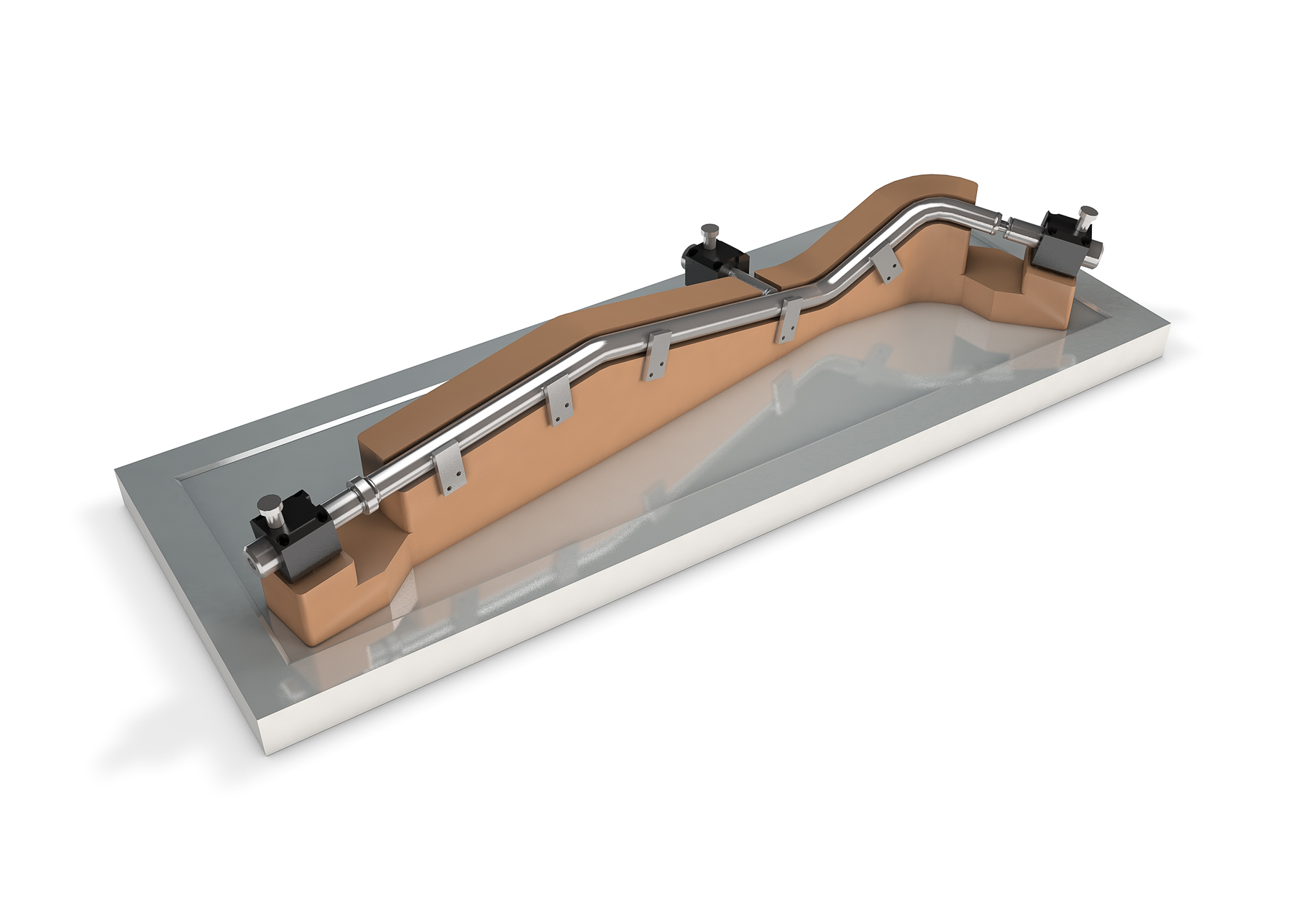

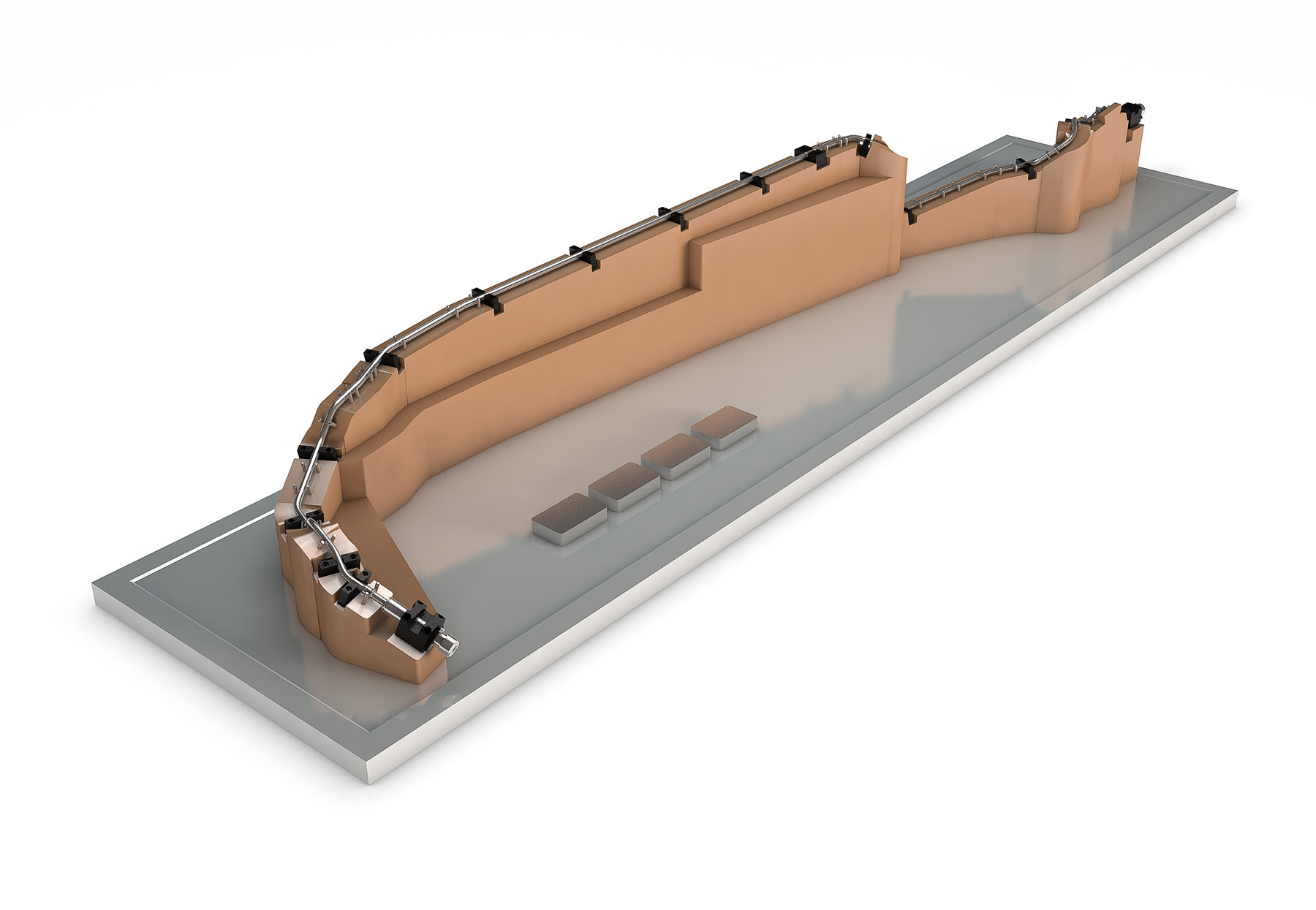

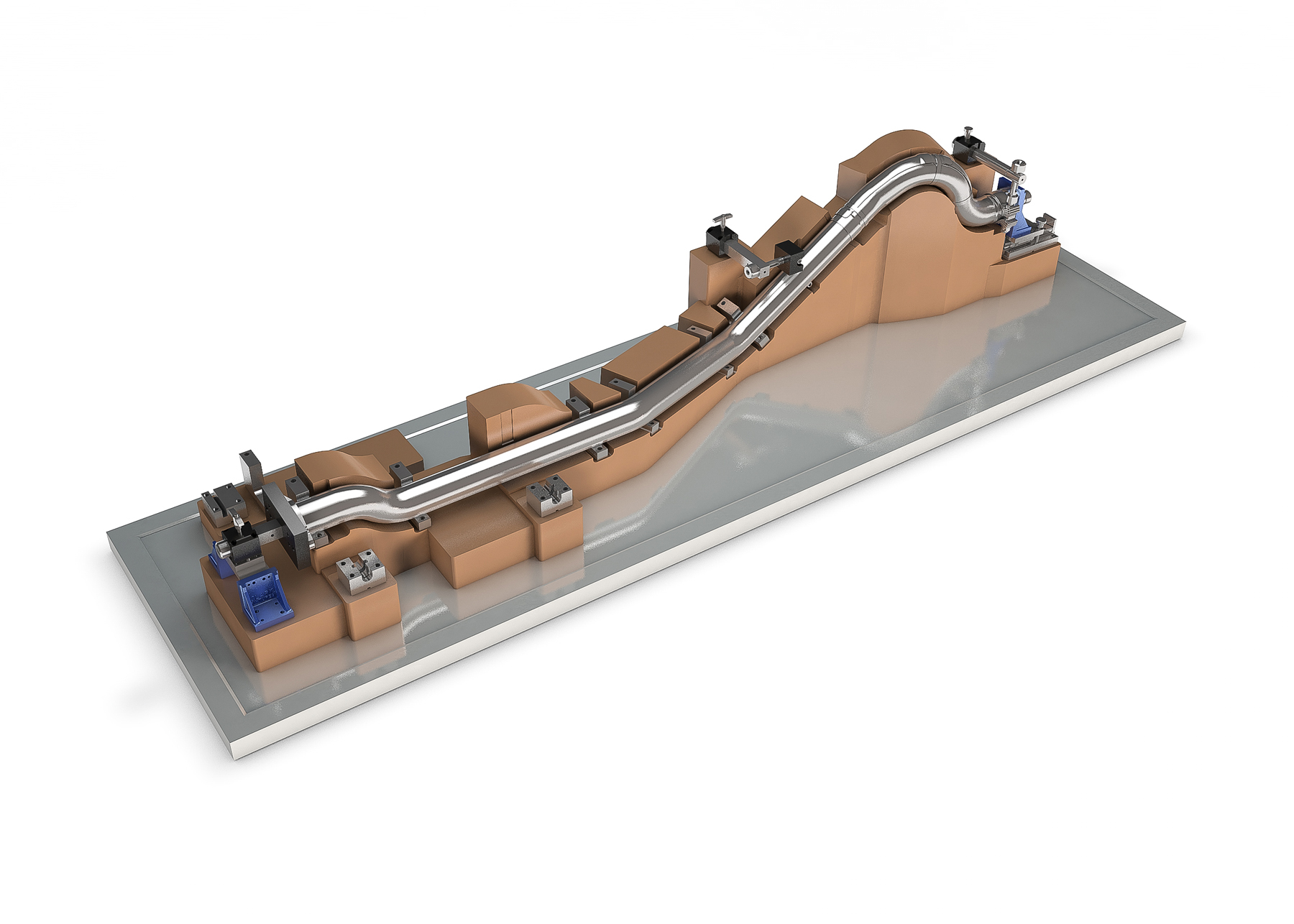

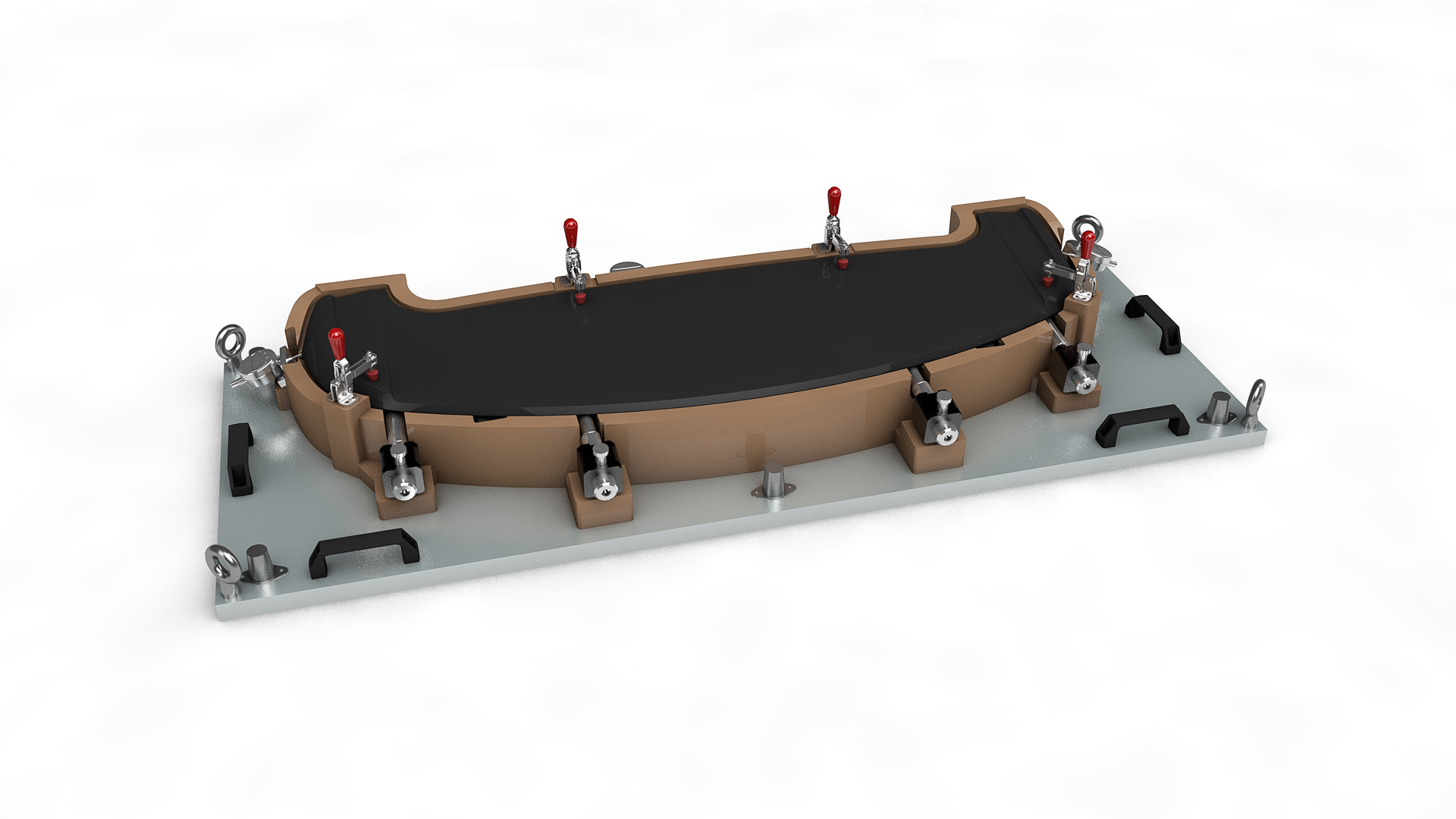

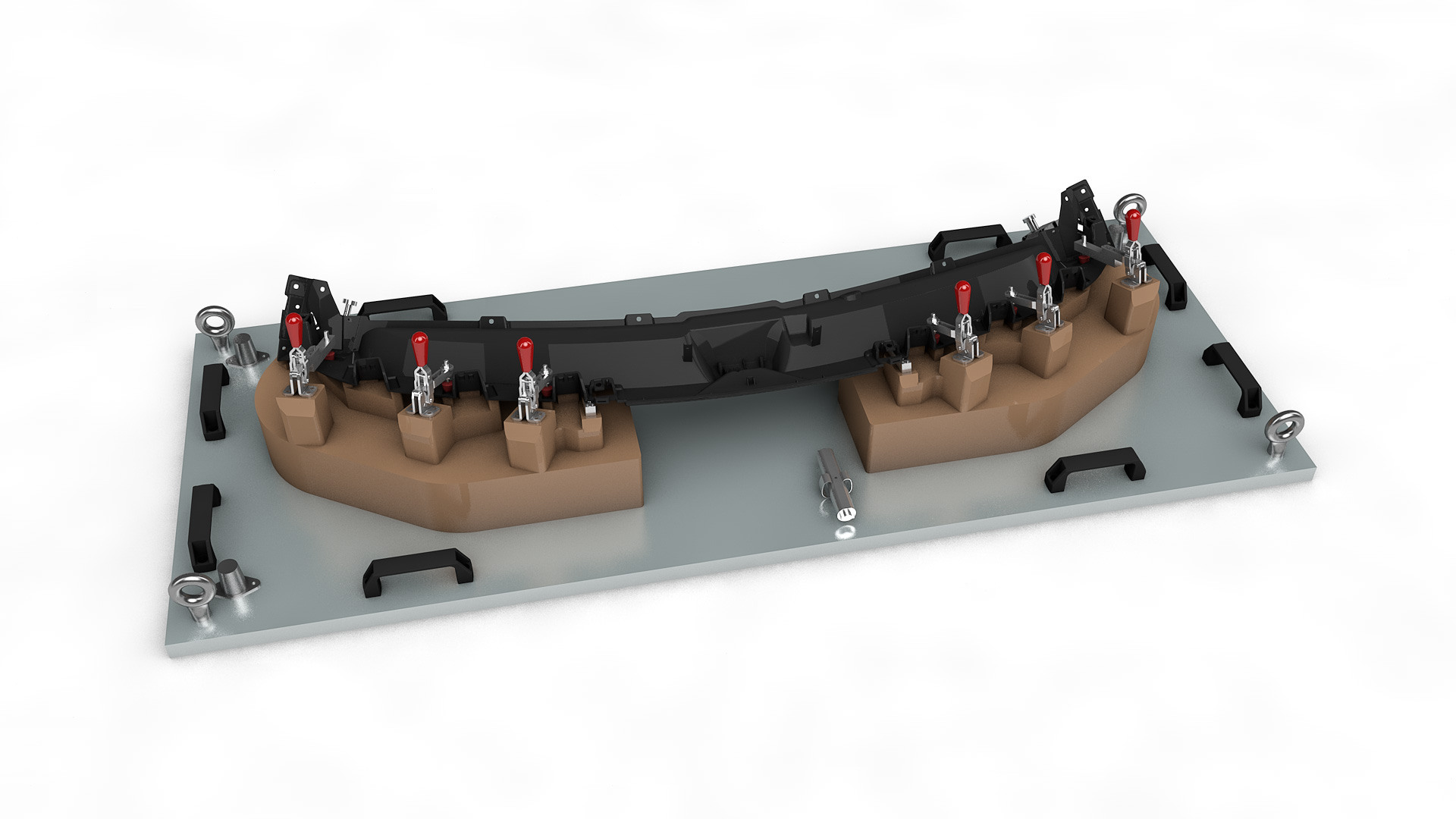

This competitively priced and quickly produced fixture is built in a durable and stable composite material. This style is ideal for bender buy-off and off the bender verification. The open “L” style provides for greater visibility, with metal tabs to hold the part in place. The end-points can be verified by simple tolerance zones or sliding component check features.

Overview

Our technology goes beyond fixtures and extends to all the materials that we use.

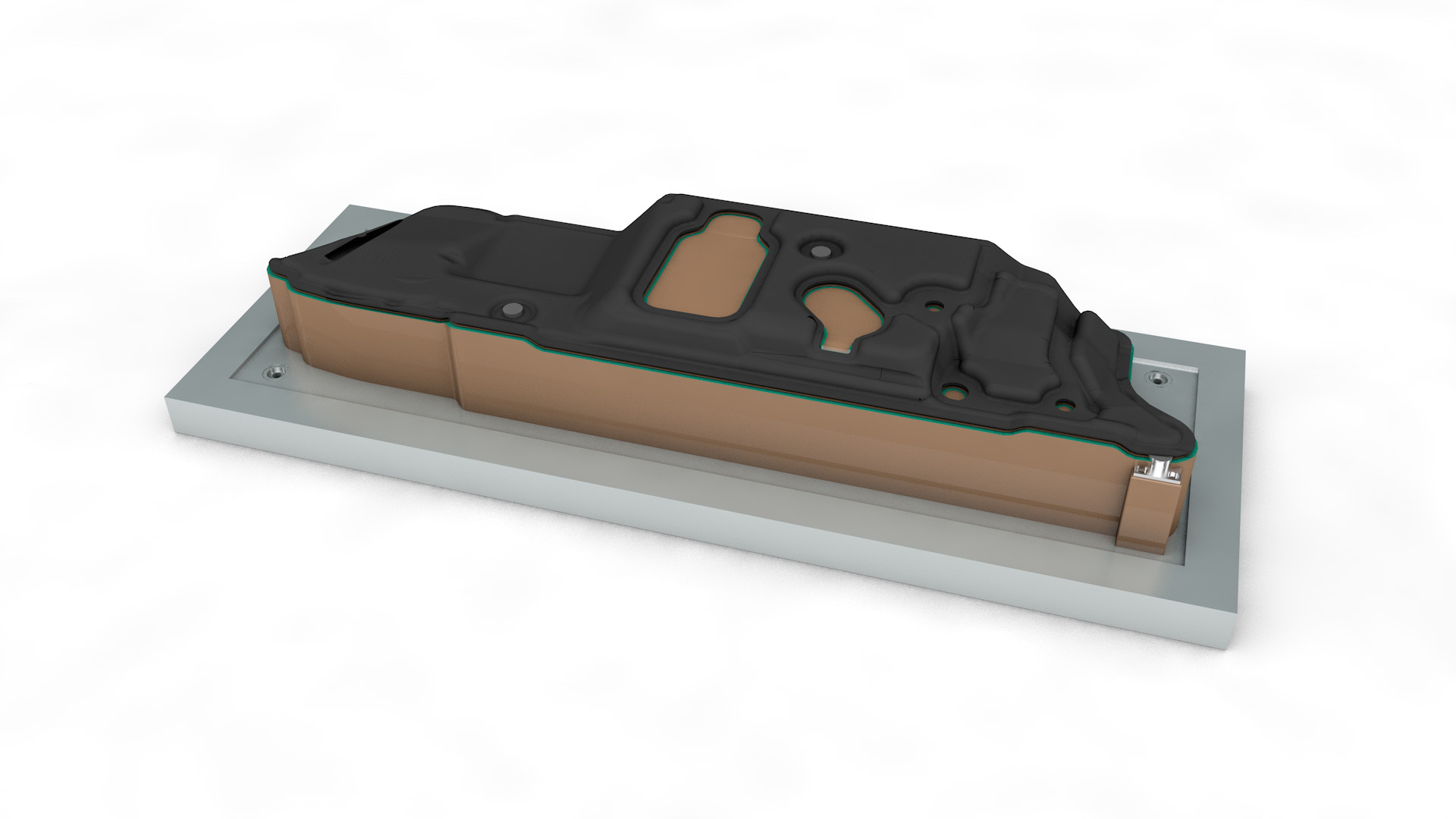

- Fixture with customer part loaded

The Base

The Clark Fixture base consists of an aluminum honeycomb core sandwiched between two sheets of aluminum and an extruded aluminum frame, which provides for stability and stiffness and reduces the weight. However, our metal stanchion fixtures are always placed on ground and polished aluminum tooling plate.

The Fixture

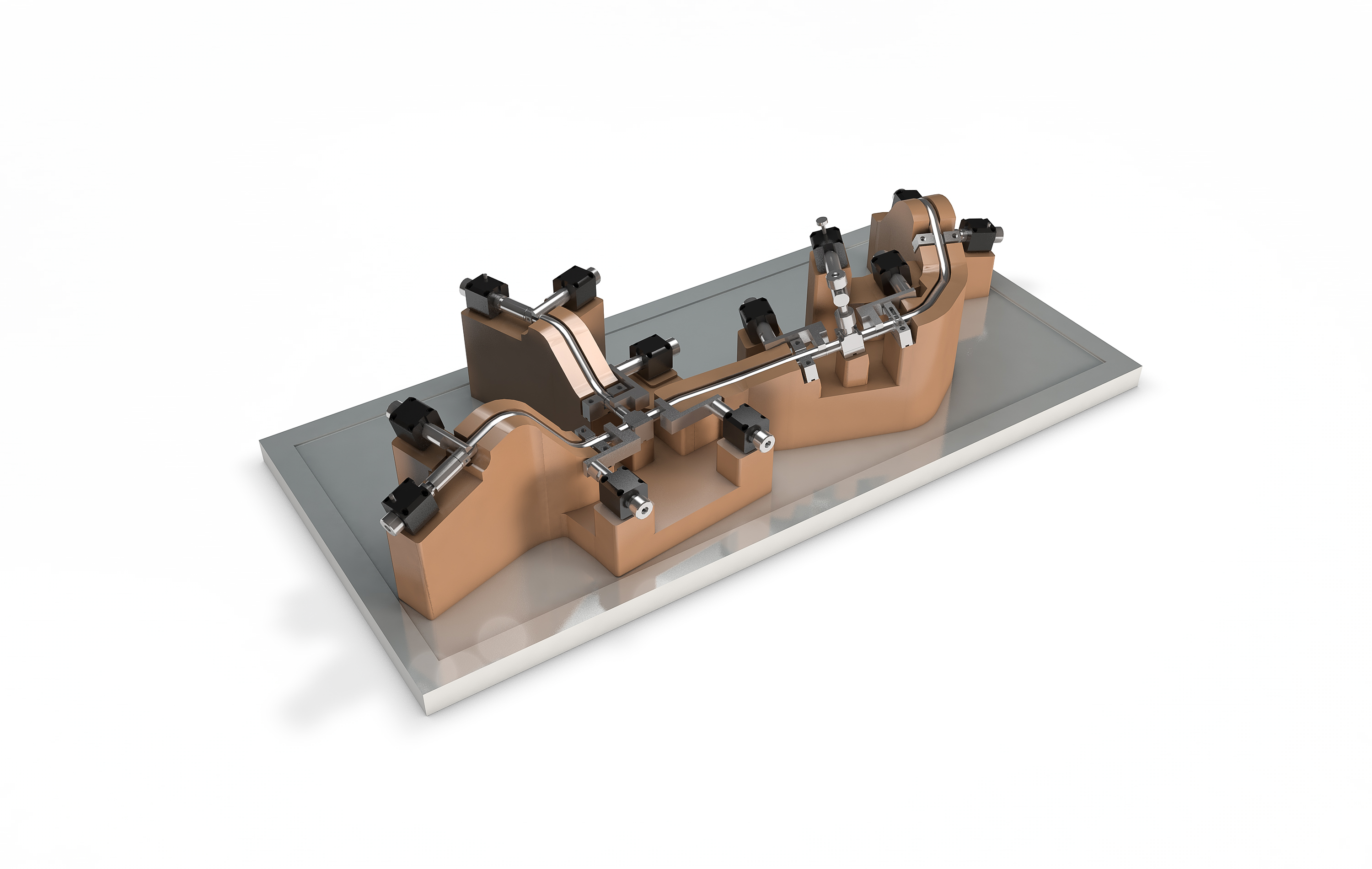

Clark Fixtures has built many of our fixtures in various foamed urethane boards. This material is durable and extremely stable. It helps reduce cost, weight, and lead-time. It also allows us to add in metal inserts where needed.

- All metal fixtures are available.

The Fixture

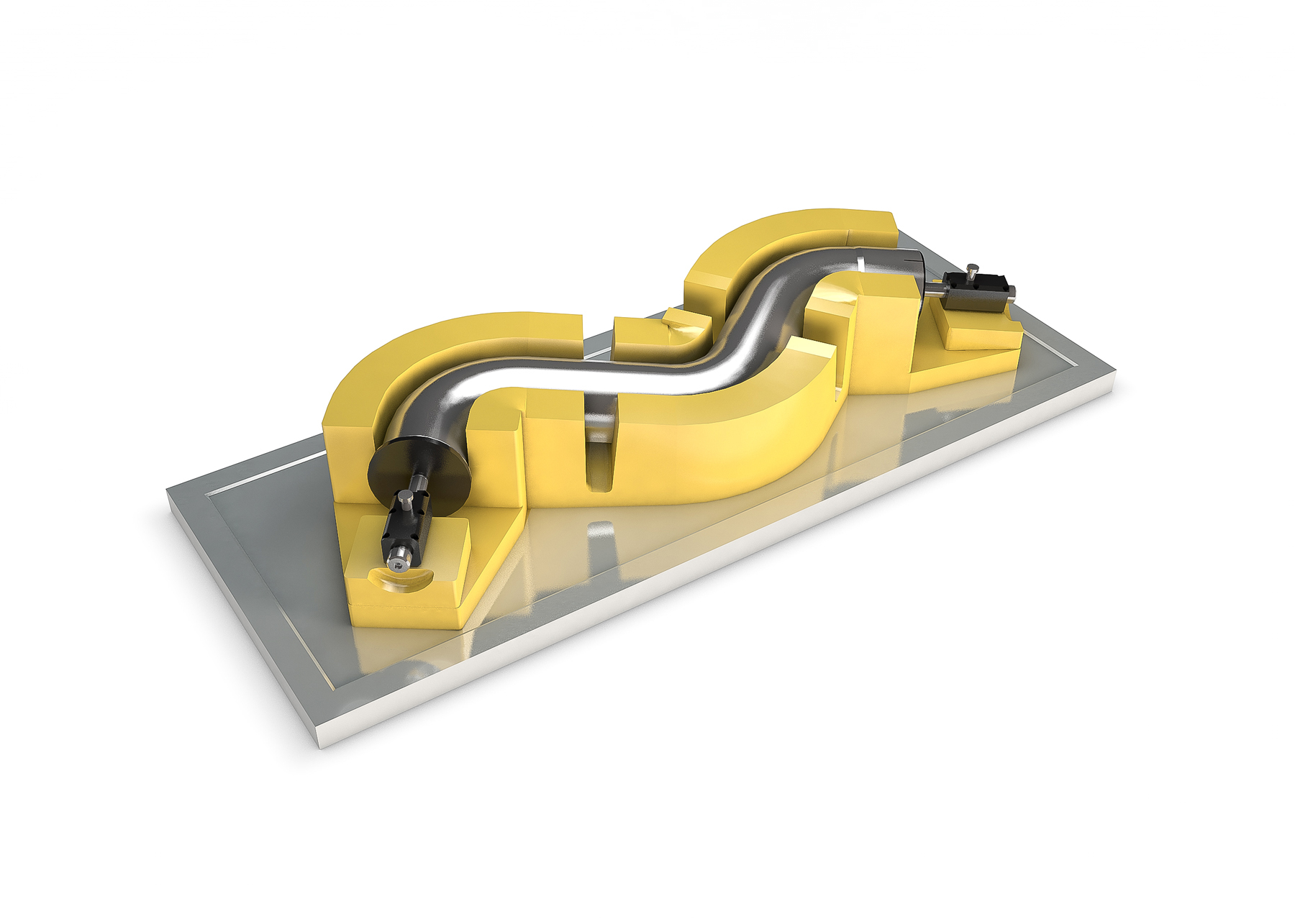

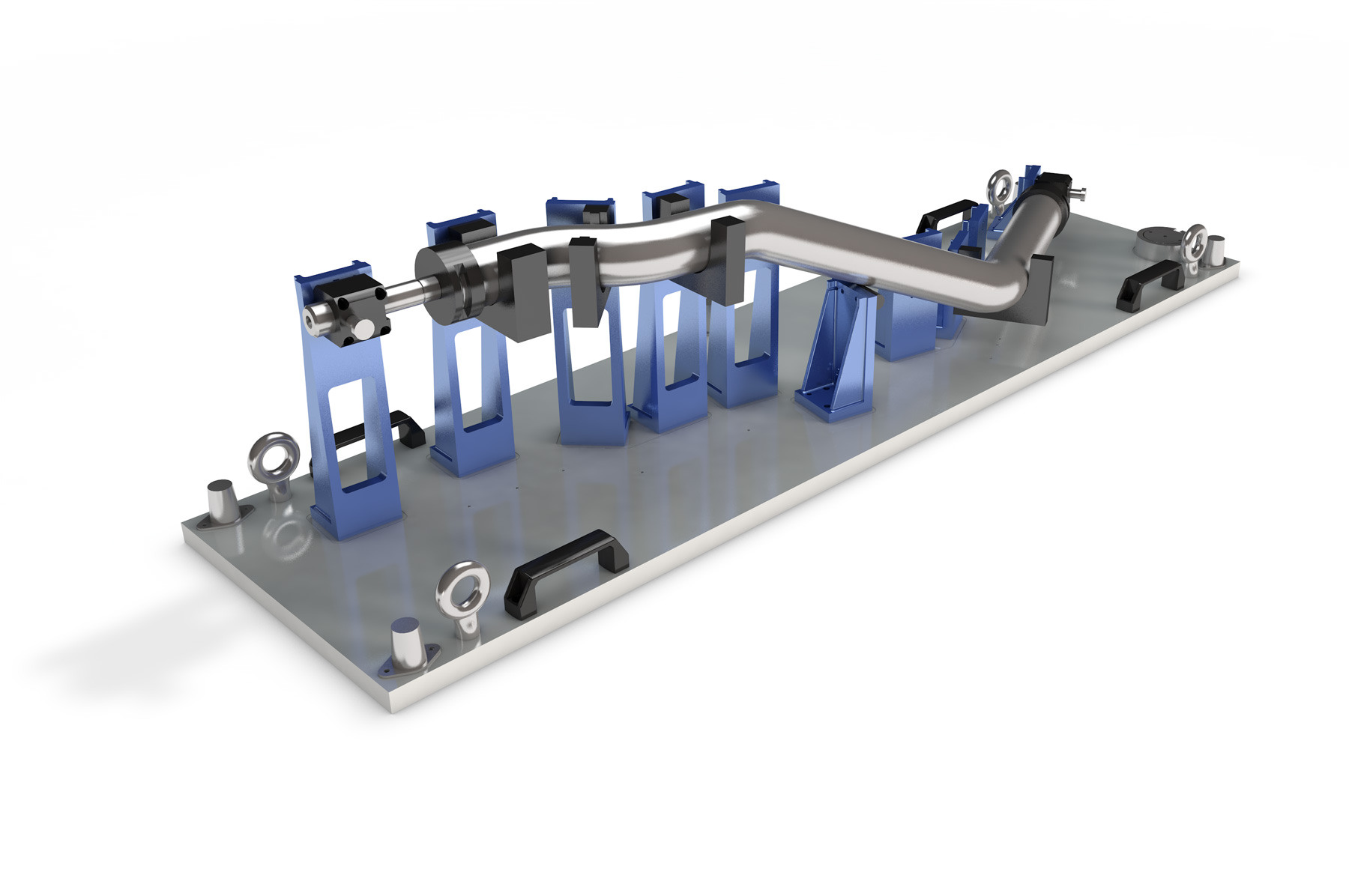

This picture represents one of the composites we use where extra durability is needed. Primarily for larger diameter tubing or rougher environments.

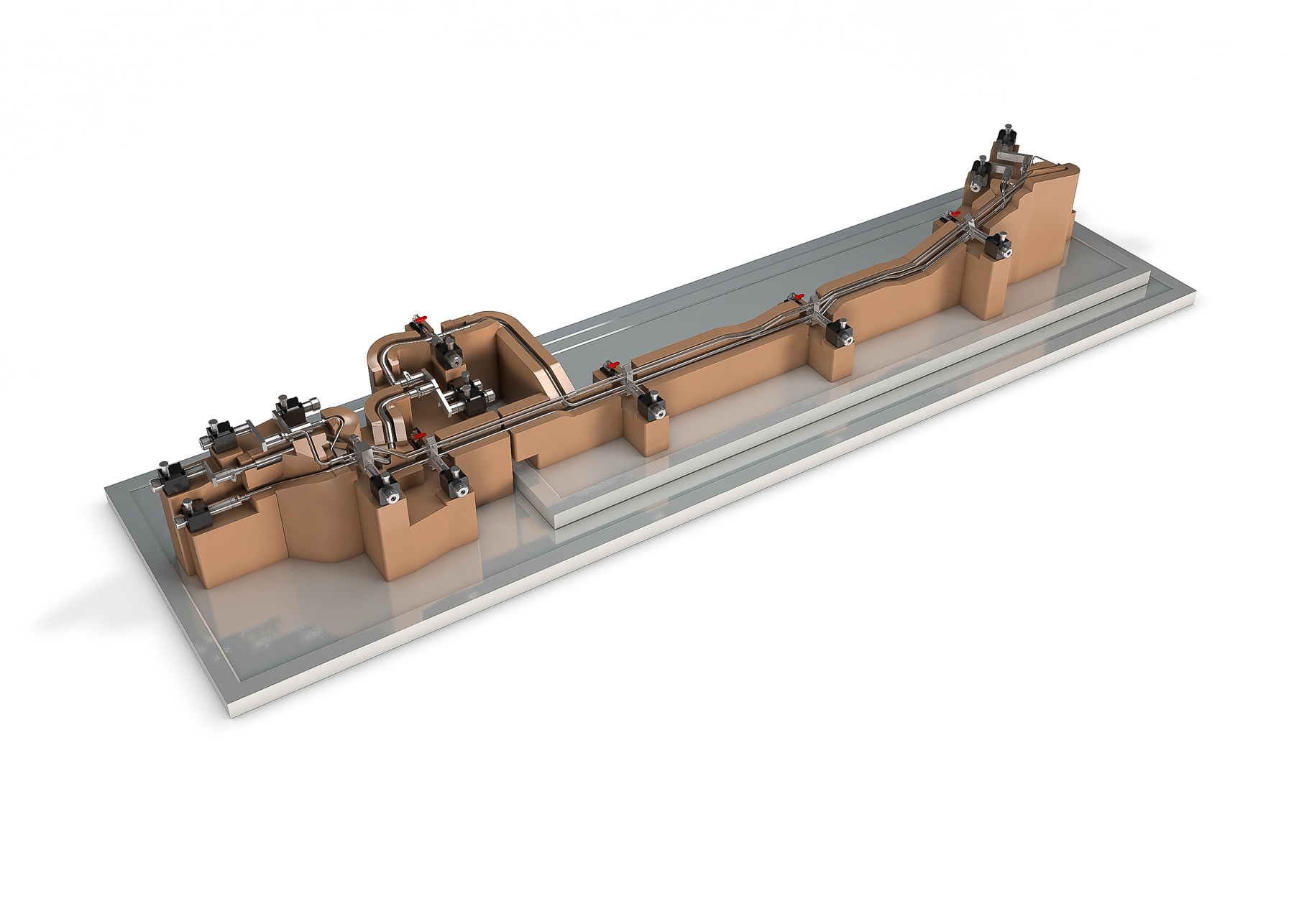

The Components

With over 40 years of experince in numerous industries, we have developed a large catalog of features that can be added to our fixtures as needed. All of these features are designed using materials to ensure precision, durability and corrosion resistance.

- End-pins

- bracket locators

- Scribe pins

- Flange clocking pins