Engineering

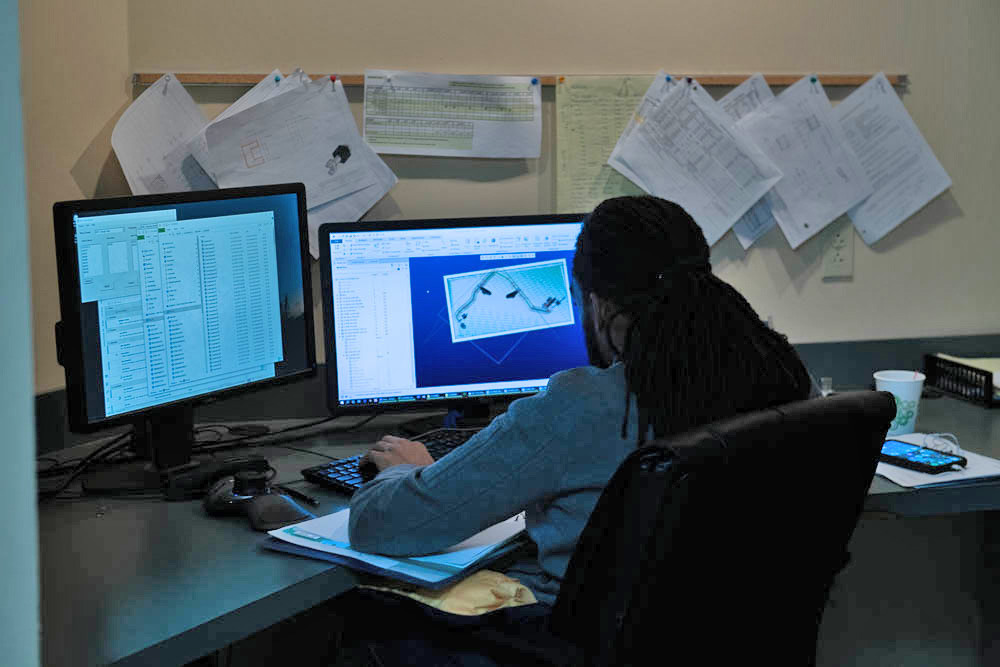

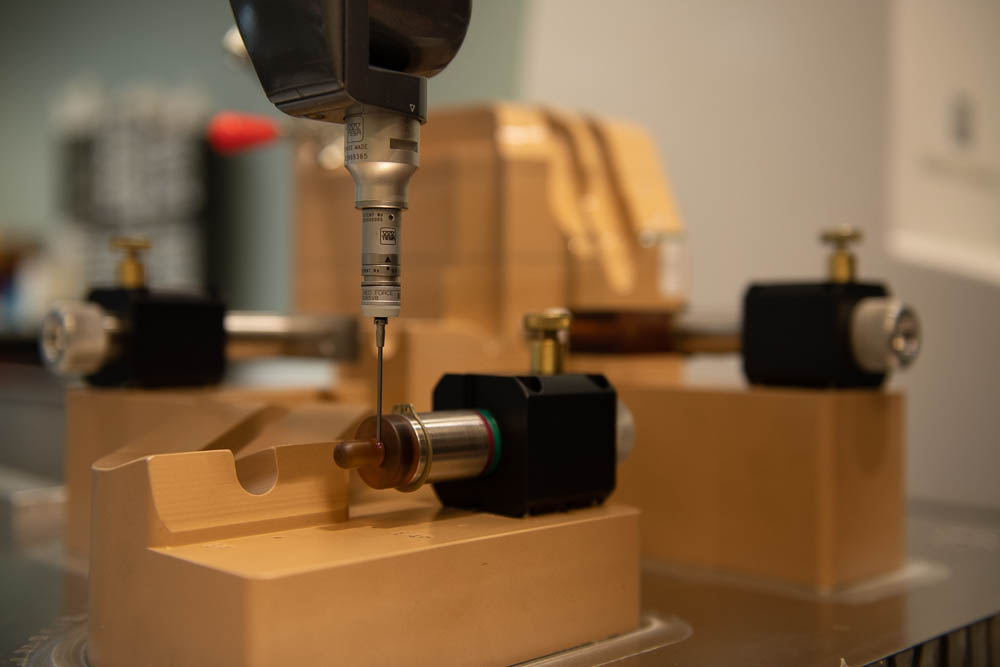

Clark Fixtures brings to the table over 40 years of experience. Our project engineers work with various customers in numerous industries. Their understanding of tolerancing and GD&T come from this experience. As new customers are on-boarded, they are assigned a PE that best fits their industry and products. This technical contact becomes your primary interface with quotes and orders.